Contact Info Contact Info

|

|

| |

Air Compressors

Case Study -- Aerospace Bearing Manufacturing Facility

It is not uncommon for air compressors to account for 20% or more of a plant's total electrical bill.

While some initiatives to reduce energy consumption are costly, many are not, and regular monitoring of electricity consumption

from air compressors can be extremely revealing. A Watts Aware WA-118 unit was installed to monitor 2 base compressors at a

bearing manufacturing plant. After less than 3 weeks of electricity use data, several cost-saving opportunities became

immediately apparent. In addition to near-term corrections, the Watts Aware system identified both long-term

improvements and ongoing maintenance needs of the compressed air system.

|

|

Compressor Changeover

Potential Cost Savings: $15,000/yr

|

|

|

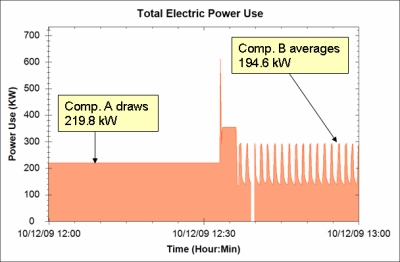

The time it takes to cross over from running compressor "A" to compressor "B" is short enough that it was assumed that the load on the

compressed air system is the same before and after the cross-over. This makes the electricity use data during a compressor cross-over ideal

for comparing compressor efficiencies. In this case, compressor "A" was purchased more recently and was thought to be

more efficient. In a matter of minutes, the Watts Aware system revealed that compressor "B" is 11% more efficient than compressor "A" under

these conditions.

|

Overloaded Compressor

Potential Cost Savings: >$5,000/yr

|

|

|

For several days of collecting data every 5 seconds from one compressor, Watts Aware recorded constant power consumption. During this time,

which included shift changes as well as limited-work days, the load on the compressor was never low enough that its electricity use would

cycle from a loaded to unloaded state. Finally, on midnight October 3, with minimal plant activity, the compressor began to cycle at a duty

cycle of 87%. These definitive data that, under normal operations, the compressor would not cycle suggested that leaks in the

compressed air system were a significant portion of the total plant's demand for compressed air. Furthermore, the compressed air system

was configured to operate at a nominal pressure too high for the compressor to support the demands of the facility. Minor modifications to

the compressor's settings could save considerable electricity usage.

|

Additional Considerations

- Ongoing Leak Management -

Watts Aware can provide periodic indicators of a compressed air system's leakage.

- Compressor Staging -

Track demand for compressed air to match compressor capacity with compressed air needs.

- Operational Adjustments -

Measure cost savings from operations changes (i.e. install low-pressure blowers where applicable).

|

Links

|

|

|

|

|

|