Contact Info Contact Info

|

|

| |

|

Applications of Watts Aware

Industrial and Commercial Electricity Cost Savings

|

|

|

Sensor Synergy's Watts Aware product line was designed with the demands of industrial and commercial energy

monitoring in mind:

|

- Manage Electricity Consumption -

Various cost saving opportunities can be realized by redistributing and replacing high-consumption

activities. These opportunities range from rescheduling activities for off-peak hours to replacing machinery with

more efficient models.

- Improve Equipment Utilization -

A close relationship exists between facility operations and power usage. Changes in equipment utilization

policies and procedures have significant effects on electricity costs.

In order to reach these goals, some important tasks must be accessible. Watts Aware was developed to make these

tasks accomplished easily:

- Identify Equipment and Operations -

Watts Aware makes it easy to match operations and equipment with power consumption data

- Track Power Usage Over Time - With data every 5 seconds and an intuitive, graphical historical data viewer,

Watts Aware provides trends by the hour, day, month, and beyond.

- Engage in Continuous Energy Saving Efforts - Energy monitoring is most effective with ongoing involvement by all stakeholders.

Watts Aware's included dashboard console provides immediately accessible, understandable data.

Monitor Air Compressor Operations in a Large Manufacturing Facility

Air compressors are used in 70% of US manufacturing facilities. Frequently these units are found to be responsible

for a large fraction of a facility's overall electricity use. Power use monitoring can reveal much information about a facility's compressed air system.

>> Click here for more info...

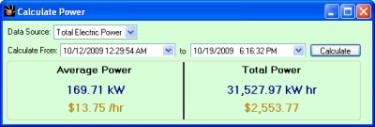

Track Whole-Facility Power Usage

- Several Watts Aware units can be monitored from a single dashboard for a comprehensive overview.

- One Watts Aware unit can monitor over 10 MW of power.

- Network-accessible data allows a variety of users to access power use data.

- Remotely compare power usage of several facilities side-by-side.

- Compare energy efficiency between shifts.

- Consider power use when scheduling electricity-intensive operations.

Monitor Individual Units or Branch Circuits

- Ideal for evaluating the cost of lighting.

- Flexible installation allows Watts Aware products to be moved to consider a variety of energy initiatives.

- Power use data can be easily annotated to identify and track individual equipment.

|

|

|

|

|

|

| |

|

|

|